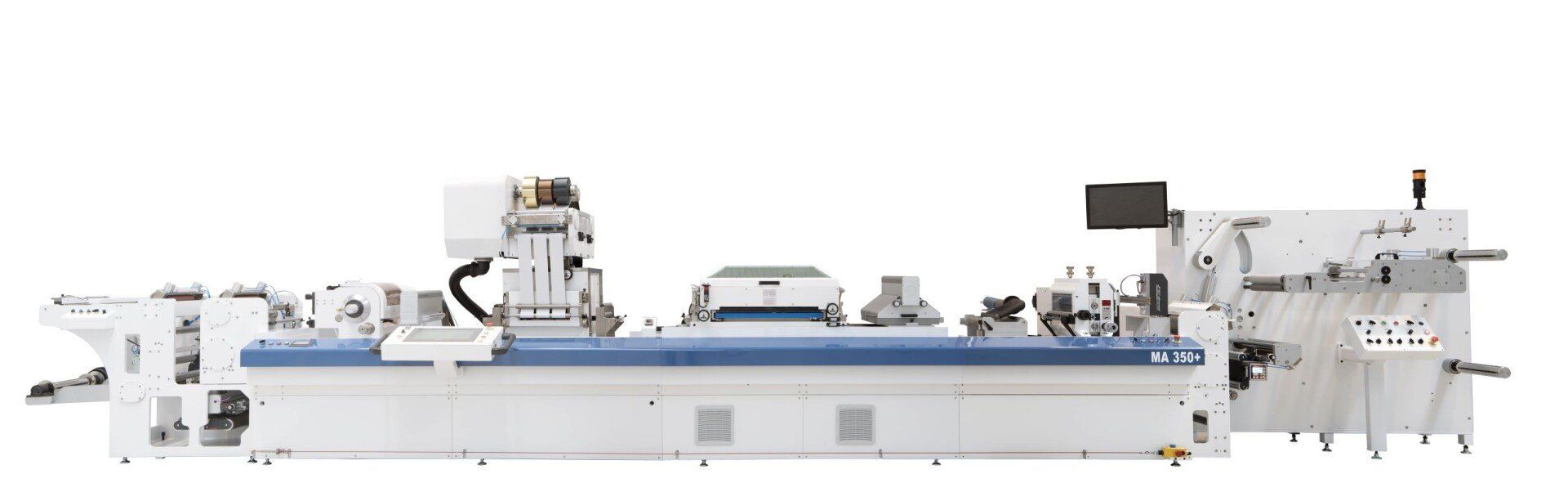

NEW EQUIPMENT

- Web width 350mm

- Printing width 105 to 330mm

- Full rotary printing size 19" 482mm

- Repeat lengths in semi rotary 435mm

- Maximum speed. 60m/min

- Flat bed embossing & cutting. 280 X 343mm

- Flat bed Hot foil stamping unit. 280 X 343mm

- Cold foil

- Flat bed Silkscreen. 330 X 330mm

- Fully rotary die cutting unit

- Turn bar

- Slitting 350mm

- 1 Matrix removal shaft 76mm

- 2 rewinding shaft 76mm

- Finished rolls diameter 800 + 400mm

- power supply AC 380 V 3 phase

For more information, please get in touch.

NEW EQUIPMENT

RL2 RL3 RL1

Lift range -180-1180 centres with 250Kg. Lift range 170-2150 centres with 135Kg

Duo lift pump technology allowing the unit to lift 6 times faster for light loads ,Saving up to 70%of lifting time,The system employs a direct drive piston arrangement ,eliminating need for maintenance of exposed chains & eliminating associated safety hazards of moving parts.

Braked rear castors:Using precision ball bearing for rotation & swivel operation,Both castors are fitted with braking mechanisms which brake both the swivel & rotation to allow additional security on inclines.

RL2 RL3 RL1

Optional : V dolly for rolls.

Capacity 650mm diameter rolls up to 250Kg

4 x durable swivel casters for easy movement around workshop.

Contact Us

We will get back to you as soon as possible.

Please try again later.